The A45 crane rail from CraneRails is a specialized track component manufactured to the stringent DIN standard (German Institute of Standards). Designed with a distinct profile optimized for crane systems, this rail provides a stable, durable, and reliable foundation for a wide range of industrial and mining applications. It is supplied in a standard length of 12 meters.

Specifications

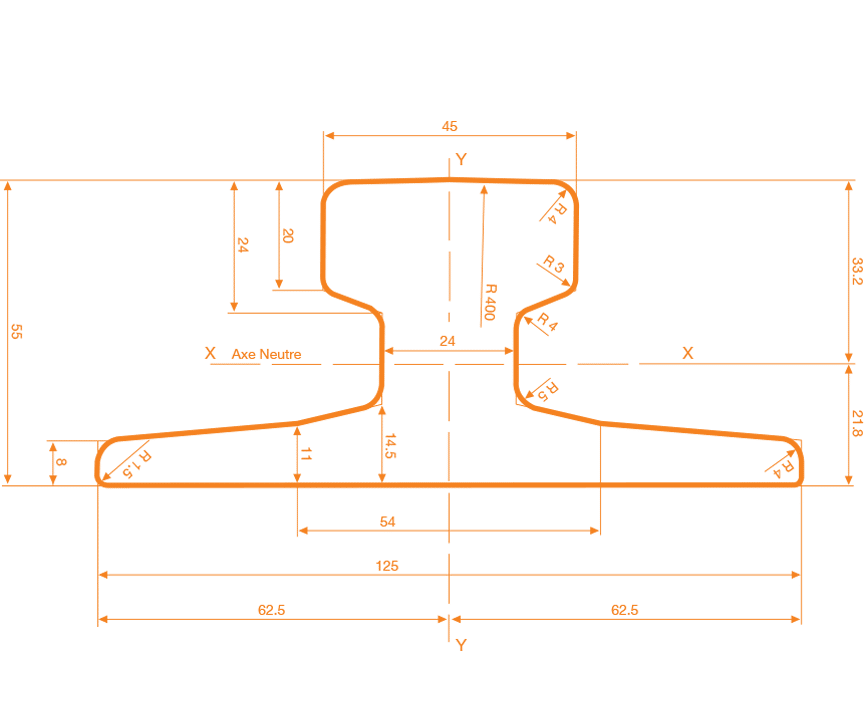

| Feature | Value | Unit |

| Rail Profile | A45 | – |

| Calculated Mass | 22.1 | kg/m |

| Standard Length | 12.0 | m |

| Head Width | 45.0 | mm |

| Base Width | 125.0 | mm |

| Web Thickness | 24 | mm |

| Elongation (Min) | 12 | % |

| Yield Point (Min) | 355 | N/mm2 (MPa) |

| Material Grade | High-quality plain carbon steel (e.g., S355JR) | – |

| Rail Height | 55.0 or 65.0 | mm |

| Tensile Strength (Min) | 690 or 590 | N/mm2 (MPa) |

The A45 crane rail’s unique profile and adherence to the DIN standard set it apart from conventional railway rails.

Key Features and Benefits

- Optimized Profile: The “A” series profile features a wide, flat top surface to evenly distribute the wheel load and a broad base to ensure maximum stability. This design is crucial for handling the immense, concentrated static and dynamic loads exerted by cranes.

- DIN Standard Compliance: Manufacturing to the DIN standard (likely DIN 536) guarantees that the rail meets specific dimensional tolerances and material properties, ensuring compatibility with standard crane wheels and safety requirements.

- Exceptional Durability: The use of high-quality steel and a robust profile gives the rail excellent resistance to wear, rolling contact fatigue, and deformation, even under heavy, repetitive use.

- Versatility: While specifically designed for cranes, its strength and profile make it suitable for a variety of other heavy-duty applications.

Applications

The A45 crane rail is a versatile and reliable choice for a number of industrial and mining uses:

- Overhead and Gantry Cranes: It is the standard track for light-to-medium duty overhead cranes and gantry systems in factories, warehouses, and workshops.

- Trolley Rails: Used to create stable and durable tracks for trolleys that transport heavy materials within industrial settings.

- Mining Rails: It can be used for specialized tracks in mining operations where a robust and stable path is required for machinery.

- Heavy-Duty Conveyors: Ideal for use in conveyor systems where a strong guide rail is needed to support heavy loads or a tripper car.

- General Industrial Applications: It is also used as a robust track for slipways and other applications where a strong, wide-based rail is required.