The A100 crane rail is a specialized, extra-heavy-duty track component manufactured to the stringent DIN standard (German Institute of Standards). This rail is the top-tier of the A-series, designed with a massive profile to provide an exceptionally stable, durable, and reliable foundation for the heaviest industrial and mining applications. It is supplied in a standard length of 12 meters.

Specifications

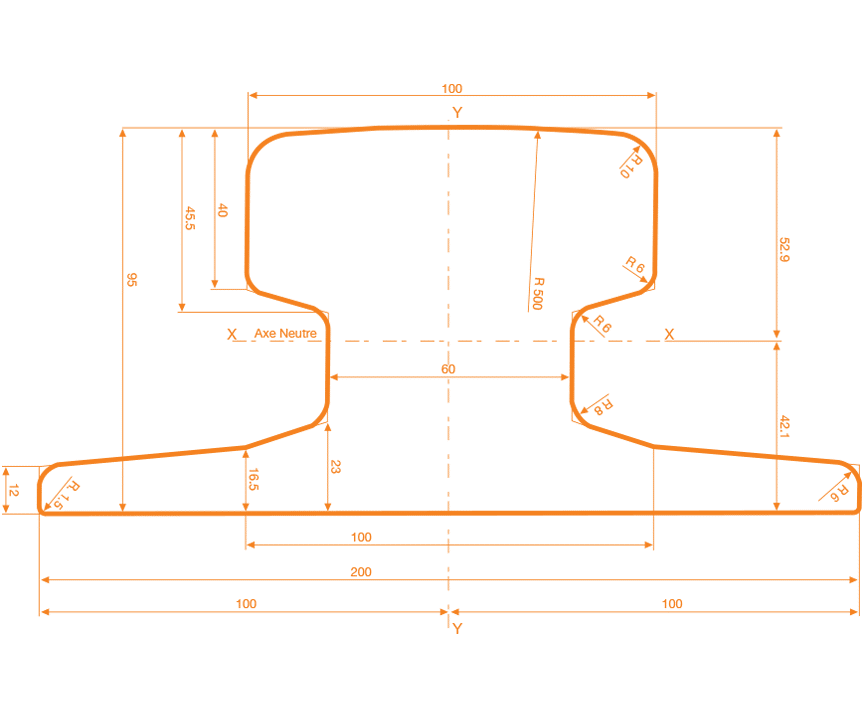

| Feature | Value | Unit |

| Rail Profile | A100 | – |

| Standard Length | 12.0 | m |

| Calculated Mass / Weight | 74.3 | kg/m |

| Rail Height | 95 | mm |

| Head Width | 100 | mm |

| Base Width | 200 | mm |

| Web Thickness | 60 | mm |

| Elongation (Min) | 8 | % |

| Tensile Strength (Min) | 880 | N/mm2 (MPa) |

| Yield Point (Min) | 440 | N/mm2 (MPa |

Key Features and Benefits

The A100 crane rail’s immense profile and adherence to the DIN standard make it the ultimate choice for the most demanding crane systems. Its design features are optimized for maximum stability and extreme load distribution.

- Ultimate Load-Bearing Capacity: The A100’s massive profile, with its wide head and base, is engineered for maximum stability and an enormous load-bearing capacity. It is specifically designed to handle the concentrated wheel loads of the largest cranes in the world.

- DIN Standard Compliance: Manufacturing to the DIN standard (likely DIN 536) guarantees that the rail meets specific dimensional tolerances and material properties, ensuring compatibility with the heaviest crane wheels and critical safety requirements.

- Exceptional Durability: The rail’s robust profile provides superior resistance to wear, rolling contact fatigue, and deformation, even under continuous, intense use in the most challenging industrial environments.

Applications

The A100 crane rail is essential for a number of high-load industrial and mining uses:

- Port and Container Cranes: It is the standard track for the largest container cranes and bulk material handlers at ports, where immense weights and constant operation are the norm.

- Shipyard Cranes: Ideal for gantry cranes used in the construction and repair of mega-vessels, providing a secure and reliable track for moving massive ship components.

- Steel Mills and Foundries: Used for cranes that handle ladles of molten metal or other heavy-duty machinery where a track of ultimate strength is required.

- Heavy-Duty Industrial Transport: It is also used as a robust track for slipways and other applications that demand a strong, wide-based rail capable of withstanding the heaviest